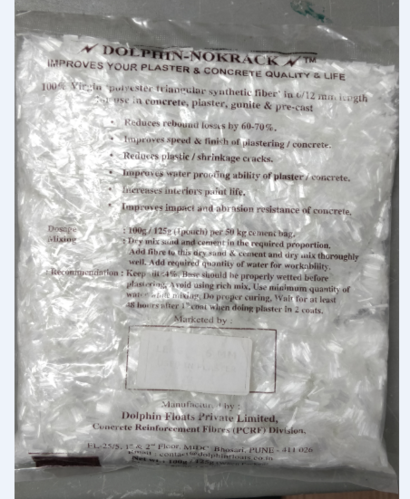

Fiber

We are leading Distributor of Synthetic Fiber in Jaipur Rajasthan India. adding fibers to the concrete will improve its freeze-thaw resistance and help keep the concrete strong and attractive for extended periods of time. Concrete by itself provides a sleek look and incredible durability for a variety of residential and commercial projects, but what if there was a simple way to increase its toughness, get a specific look and feel, and even minimize cracking? There is, thanks to concrete fibers. Fiber-reinforced concrete has been rapidly growing throughout the building industry since contractors and homeowners started to recognize its many benefits. Macro and steel fibers are advantageous for industrial projects, while stealth and micro fibers are beneficial for residential projects. Before you place your next concrete order, consider the following five reasons you should put fiber in your concrete.

- INCREASE TOUGHNESS AND DURABILITY

- DECREASE CRACKING

- IMPROVE FREEZE-THAW RESISTANCE

- REDUCE EFFECTS OF SHRINKAGE

- LOOK

APPROVALS

- 1. Bureau of Indian Standards (BIS) & Indian Road Congress (IRC) have acknowledged the product as follows:

- 2. IS:456:2000 – Amendment No.7, 2007 This Code gives recognition for use of fibres for special applications in concrete.

- 3. IRC:44-2008 – Cement Concrete Mix Designs for Pavements with fibres These guidelines are for design mix for pavement quality concrete where Polyester fibres have been allowed to use under materials of design mix.

- 4. IRC:SP:76:2008 – Guidelines for Ultra Thin White Topping with fibres These guidelines are for mandatory use of Polyester fibres also in ultra thin white topping

- 5. Vision : 2021 by Ministry of Surface Transport, New Delhi This document highlights that fibre reinforce concrete is very important technology to achieve Vision: 2021 with good durable Concrete Roads.

- 6. CPWD – DELHI SCHEDULE OF RATES – 2007 (FIRST REPRINT) CURRECTED UPTO MARCH 2010 CODE NO. 8732, 8733, ITEM NO. 4.18 & 13.79.

- 7. "Indian Railway Unified Standard Specification (Works & Materials) – 2010 by Engineering Department. Item No. 4.11 Chapter No. 04 – Reinforced Cement Concrete.

- 8. Northern Western Railway - Rajasthan Schedule of Rates” (SSR) - 2010 Item No. 045030

Central GOVT. APPROVALS

- 1 Public Works Department Jaipur Rajasthan

- 2 Water Resources Department Rajasthan

- 3 Punchyati Vibhag Jaipur Rajasthan

- 4 RUIDP

- 5 Rajasthan State Road Development Corporation Jaipur

- 6 Public Health Engineering Department Jaipur Rajasthan

- 7 Jaipur Municipal Corporation Jaipur

- 8 PUBLIC WORKS DEPARTMENT

- 9 BSR – 2010 Building Work Code No. 15.29 & 15.30.

- 10 BSR – 2010 ROAD WORK Item No. 16.56 & 16.58

- 11 BSR – 2010 NH Circle Chapter No. 16, Item No. 14 & 15.